Continuous Casting Billet Defects

Continuous casting machines are equipment used in the steel industry to produce high-quality steel billets. These continuous casting billet defects are critical to ensure the production of defect-free billets. In this article, we will explore together.

Advantages of Electric Induction Heating Furnace

Electric induction heating furnace can quickly and efficiently heat metals and other materials and are essential equipment in the steel and metal smelting industry. This article will discuss with you the advantages of induction heating furnaces.

Steel Billet Production Process

The steel billet production process is a critical step in the manufacturing of steel products. Steel billets are the raw material for a variety of steel products, including rods, rods, and wire. This article aims to provide an overview of the billet production process, from the initial stages of raw material preparation to the final stages of billet shaping.

Induction Furnace Steel – HANI

Induction furnace steel is an important equipment in the steel industry. This article will explore how induction furnaces work, their advantages, and their applications in the steelmaking process.

Billet Manufacturing – CCM

Billet manufacturing is an integral part of the steel production process and this article explores the process of making billets using continuous casters and highlights their advantages over traditional methods.

About Industrial Silicon For EAF

About industrial silicon, also known as metallic silicon, is an important raw material for the production of electric arc furnaces (EAF). This article aims to gain an in-depth understanding of the role of industrial silicon in electric arc furnaces, its properties, applications and its impact on the steelmaking industry.

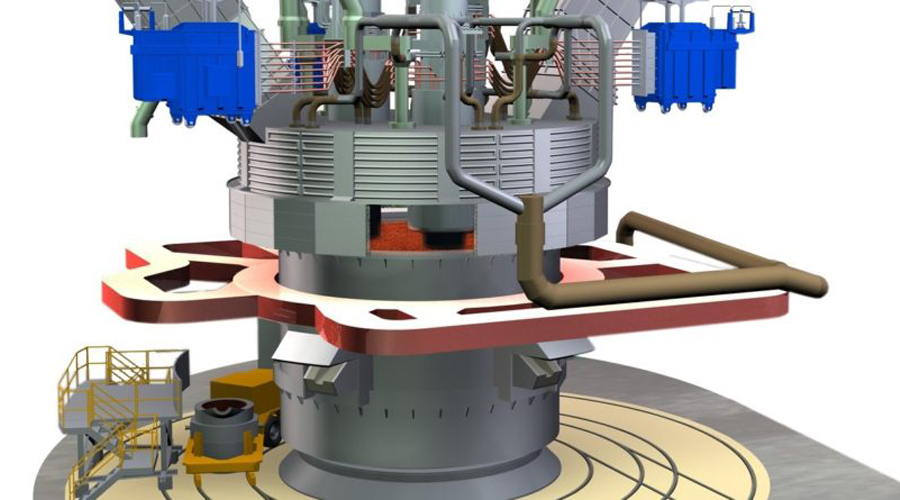

How Does A Submerged Arc Furnace Work

SAF are important industrial equipment used in the production of various metals. This article explores the inner workings and processes of operating a submersible furnace. Introduces how does a submerged arc furnace work.

Continuous Caster – What Does It Do?

As a popular equipment in the metal smelting industry, continuous caster can convert molten metal into solidified steel and produce high-quality products through efficient continuous casting.

Induction Furnace Of Steel

This article mainly introduces the characteristics of induction furnace of steel melting and its advantages in the steel industry.

Ladle Furnace Transformer Maintenance

Ladle furnace transformer maintenance plays a vital role in the steelmaking industry. Therefore, regular maintenance is essential to ensure its reliable performance and prevent costly failures.