Induction Furnace Upgrades

Induction furnace upgrades can solve many existing problems in induction furnace plants. In order to provide users with the highest safety, energy-saving, and easy-to-operate induction furnaces in the industry, our company also provides induction furnace upgrades services.

Inductotherm Furnace for Sale

An inductotherm furnace for sale is a device that converts three-phase power frequency alternating current into direct current after rectification and then converts the direct current into the adjustable current to supply the alternating current flowing through the capacitor and induction coil.

Steel Induction Furnace for Sale

The round steel induction furnace for sale is a non-standard induction heating equipment designed for heating before forging, rolling, or quenching and tempering heat treatment of round steel.

Aluminum Induction Melting Furnace for Sale

Aluminum induction melting furnace for sale can be divided into tilting melting furnace, top-out melting furnace, and fixed intermediate frequency melting furnace.

Induction Furnace+Vertical Continuous Casting Machine

Do you want to know the principle of induction furnace+vertical continuous casting machine? Do you know the advantages and disadvantages of an induction furnace+vertical continuous casting machine?

Induction Furnace Price in India

The induction furnace price in India must be different, because there are countless manufacturers selling induction heating furnace equipment for steel bars in the market. If there are differences in manufacturers, the prices may vary.

Induction Heating Furnace for Sale

This set of induction heating furnace equipment for sale is designed as an integrated device. The intermediate frequency power supply is integrated with the inductor and auxiliary machinery.

Induction Furnace Manufacturers in India

Are you looking for induction furnace manufacturers in India? Hani Metallurgy is one of the professional induction furnace manufacturers in China, focused on the development, design, and production of various specifications of heating furnace equipment.

Induction Furnace for Aluminum

The induction furnace for aluminum is mainly used for smelting and heating of aluminum and aluminum alloys, especially in smelting places where there are many recycled materials such as aluminum profiles and aluminum products

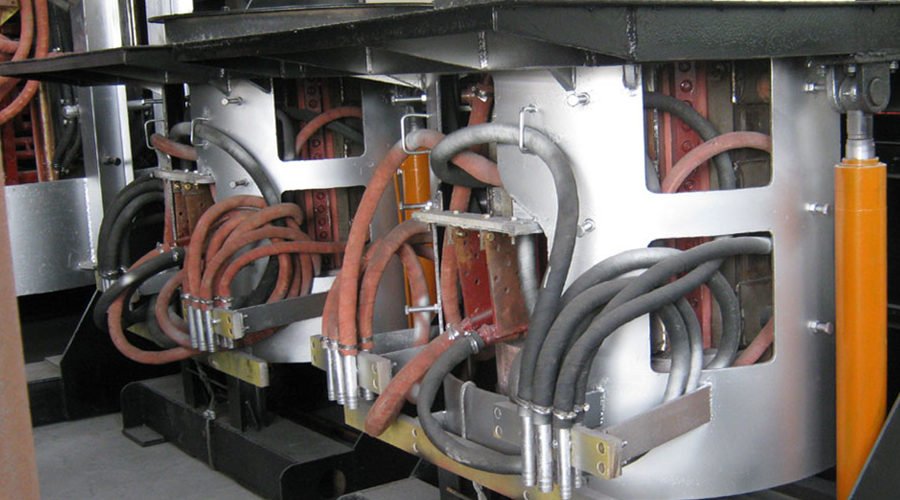

Induction Furnace Lining Life

How to improve the induction furnace lining life? An induction furnace is a high-temperature electric furnace heated by the eddy current effect, which is composed of a furnace body, electrical system, water cooling equipment, and tilting mechanism.