The round steel induction furnace for sale is a non-standard induction heating equipment designed for heating before forging, rolling, or quenching and tempering heat treatment of round steel. It is equipped with an automatic control system and auxiliary mechanical equipment to form a complete intelligent fully automatic induction heating production line. It is also the preferred equipment for the construction of intelligent factories at present.

1. Composition of Round Steel Induction Furnace

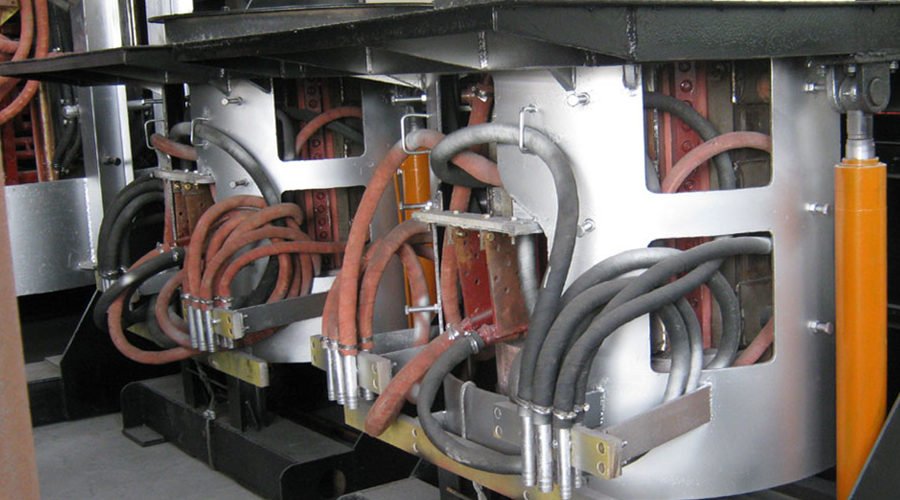

The round steel induction furnace is composed of a heating thyristor power supply, inductor coil, cylinder pushing system, rhythm controller, temperature measurement system, temperature sorting system, touch screen operation system, temperature display screen, etc. If a round steel induction furnace production line is required, customized feeding and discharging devices, automatic feeding machine, discharging machine, discharging separators, and closed cooling water circulation systems are also required.

2. Parameters of Round Steel Induction Furnace for Sale

2.1 Specific Configuration of Ф70mm×240mm Round Steel Induction Heating Furnace

Round steel: Ф70-80 × 240 overall heating, one piece per 32 seconds.

Heating temperature: 1200 ℃

Requirement: The equipment power is designed according to 400KW, with frequency fo=750HZ and f=1000HZ. Three compensating capacitors are actually used, and the flat crimping method (0.75-1000-1S) is used.

Size: L * W * H=2300 * 500 * 560.

Inductance parameters: Φ135 × 2250 × 66 turns, square copper tube 24 × 16 × 2.5 flat winding (effective welding pad surface 24mm), the first group of 10 turns at the feeding end, and the remaining 7 groups of 8 turns, with a total of 66 turns in series. The theoretical gap is 9.7mm, and the binding material is the CA340 model, with furnace lining holes Φ105.

The guide rail adopts Ф14 * 2 stainless steel pipe, bidirectional water cooling.

Core winding mold: Φ135 * 450 per piece

Knot mold: Φ105 * 2500 per piece

2.2 Specific Configuration of Ф90mm×280mm Round Steel Induction Heating Furnace

Round Steel: Ф90 × 280mm overall heating, one piece in 60 seconds.

Heating temperature: 1200 ℃

Requirement: The equipment power is designed according to 400KW, with frequencies fo=500HZ and f=800HZ. The compensation capacitor is actually connected to 3 flat voltages (0.75-1000-1S).

Size: L * W * H=2300 * 500 * 560.

Inductance parameters: Φ165 × 2250 × 72 turns, square copper tube 24 × sixteen × 2.5 flat winding (effective pad surface 24mm), 8 turns in a group, 9 sets in series, a total of 72 turns, with a theoretical gap of 6.9mm. The knotting material is the CA340 model, and the furnace lining hole is Φ135.

The guide rail adopts Ф16 * 2 stainless steel pipe, bidirectional water cooling.

Core winding mold: Φ165 * 450 per piece

Knot mold: Φ135 * 2500 per piece

2.3 Specific Configuration of Ф65mm×320mm Round Steel Induction Heating Furnace

Round steel: Ф65-80 × 320, 7-hole end heating, every 43 seconds.

Heating temperature: 1200 ℃

Requirement: The equipment power is designed to be 400KW, with a frequency of fo=750HZ and f=1000HZ. The compensation capacitor is actually connected to three flat voltages (0.75-1000-1S)

Size: L * W * H=1900 * 450 * 560.

Inductance parameters: per holeΦ 130 * 370 * 11 turns, square copper tube 24 * 16 * 2.5 flat wound (effective heating surface 24), a set of 11 turns, theoretical gap 7.45mm, furnace lining carbonization Φ125* Φ105 * 450 silicone hose with a total of 7 holes.

Core winding mold: Φ 130 * 450 per piece

2.4 Specific Configuration of Ф95mm×320mm Round Steel Induction Heating Furnace

Round steel: Ф 95-105 × 320, 7-hole end heating, every 72 seconds.

Heating temperature: 1200 ℃

Requirement: The equipment power is designed according to 400KW, with frequencies fo=600HZ and f=800HZ. The compensation capacitor is actually connected to 3 flat voltages (0.75-1000-1S)

Size: L * W * H=1900 * 420 * 560.

Inductance parameters: per hole Φ150 * 370 * 11 turns, square copper tube 24 * 16 * 2.5 flat wound (effective heating surface 24), a set of 11 turns, theoretical gap 7.45mm, furnace lining carbonization Φ145* Φ125 * 450 silicone hose with a total of 7 holes.

Winding core mold: Φ150 * 450 per piece

3. Characteristics of Round Steel Induction Furnace

3.1 Round steel induction furnace heating, less oxidation and decarbonization. Due to the principle of medium frequency induction heating being electromagnetic induction, its heat is generated within the workpiece itself. Therefore, the workpiece heated by the round steel induction furnace has less oxide skin, good heat permeability, good process repeatability, and stable performance.

3.2 The round steel induction furnace has a high degree of automation and can achieve fully automatic unmanned operation. By selecting automatic feeding and automatic discharge sorting devices, combined with our company’s control, the fully automatic unmanned operation can be achieved. Ordinary workers can continue working on forging tasks within a few minutes after using a medium-frequency electric furnace, without the need for furnace workers to perform furnace burning and sealing work in advance.

3.3 The round steel induction furnace heats evenly. Temperature control is achieved by selecting a reasonable operating frequency to adjust suitable heat transfer and uniform heating. Improve product quality and qualification rate through temperature control.

3.4 The working environment of the round steel induction furnace is superior, improving the working environment of workers and the company image. Compared with coal stoves, low-energy induction heating furnaces ensure that workers do not become too thin to bake or smoke, meeting the various indicators and requirements of the environmental protection department. At the same time, they establish the company’s external image and the future development trend of the forging industry.

3.5 Low energy consumption of round steel induction furnace. Compared with other heating methods, induction heating has lower energy consumption and all indicators meet the requirements of national standards. The energy-saving heating method in the round steel induction furnace is to heat from room temperature to 1100 ℃, and the power consumption of the ton forging is less than 360 degrees.

3.6 The induction furnace body of the round steel induction furnace is easy to replace and occupies a small area. Configure different specifications of induction furnace bodies according to the size of the processed workpiece. Each furnace body is equipped with a conversion joint, making it easy and convenient to replace the furnace body.