Advantages of Electric Induction Heating Furnace

Electric induction heating furnace can quickly and efficiently heat metals and other materials and are essential equipment in the steel and metal smelting industry. This article will discuss with you the advantages of induction heating furnaces.

Induction Furnace Steel – HANI

Induction furnace steel is an important equipment in the steel industry. This article will explore how induction furnaces work, their advantages, and their applications in the steelmaking process.

Vacuum Induction Melting Furnace Principle

The principle of vacuum induction melting furnace is based on the process of induction heating and vacuum technology. This type of furnace is designed to melt metals in a vacuum environment, which helps to remove impurities and improve the quality of the final product.

Induction Furnace Of Steel

This article mainly introduces the characteristics of induction furnace of steel melting and its advantages in the steel industry.

Induction Furnace Principle & Advantage

This article mainly introduces the induction furnace principle: it uses electromagnetic induction to generate heat in metal, thereby realizing various metal smelting. and discuss its applications & advantages.

Selection of Intermediate Frequency Furnace Equipment

The intermediate frequency furnace is a commonly used non-standard induction heating equipment for metals. Because it is a non-standard heating equipment, there

Iron Induction Furnace

Iron induction furnace is a furnace that uses electromagnetic induction to heat and melt iron. The article mainly describes its principle, characteristics, advantages and it is widely used in foundry and metal processing industry to produce cast iron and steel etc.

Induction Furnace Heating Principle

The induction furnace heating principle is based on the interaction between a conductive material and a magnetic field generated by an alternating current. That is, through the principle of electromagnetic induction, the furnace can efficiently and effectively heat the metal to an extremely high temperature. This article takes a deep dive into the fascinating world of induction furnace heating, exploring how it works, its benefits and applications.

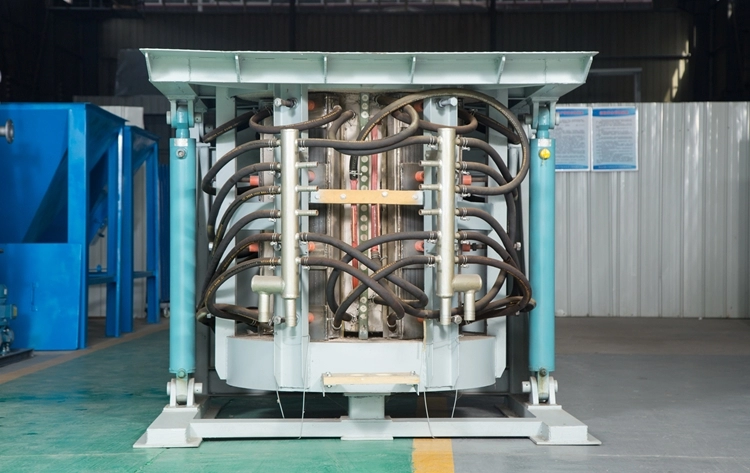

10 Ton Induction Furnace

The 10-ton induction furnace is a common industrial heating equipment, which is widely used in metal smelting, heat treatment and other fields. This article will introduce the composition, working principle and technical parameters of the 10-ton induction furnace.

Electromagnetic Induction Slag Melting Furnace

Electromagnetic induction slag smelting furnace is an ideal smelting furnace for efficient use of slag sensible heat in blast furnaces, submerged arc furnaces, etc., and one-step production of rock wool.