How Does A Submerged Arc Furnace Work

SAF are important industrial equipment used in the production of various metals. This article explores the inner workings and processes of operating a submersible furnace. Introduces how does a submerged arc furnace work.

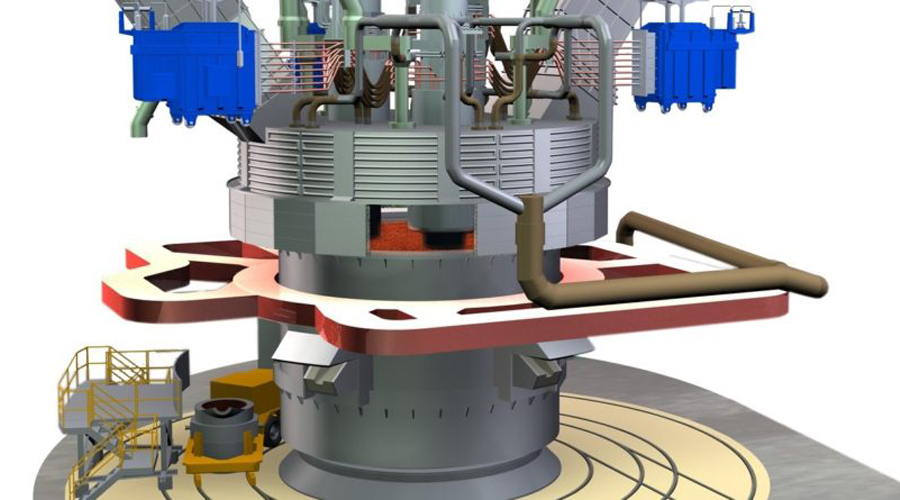

The Role of Submerged Arc Furnace Diagram

Submerged arc furnace diagram is an important step before the production of metal smelting equipment. The purpose of this article is to explore the significance of submerged arc furnace diagrams and their role in the production of various materials through the submerged arc furnace process.

Submerged Arc Furnace For Ferro Alloy Production

This article mainly describes the specific characteristics of submerged arc furnace for ferro alloy production, as well as the principle, advantages and applications of induction furnaces.

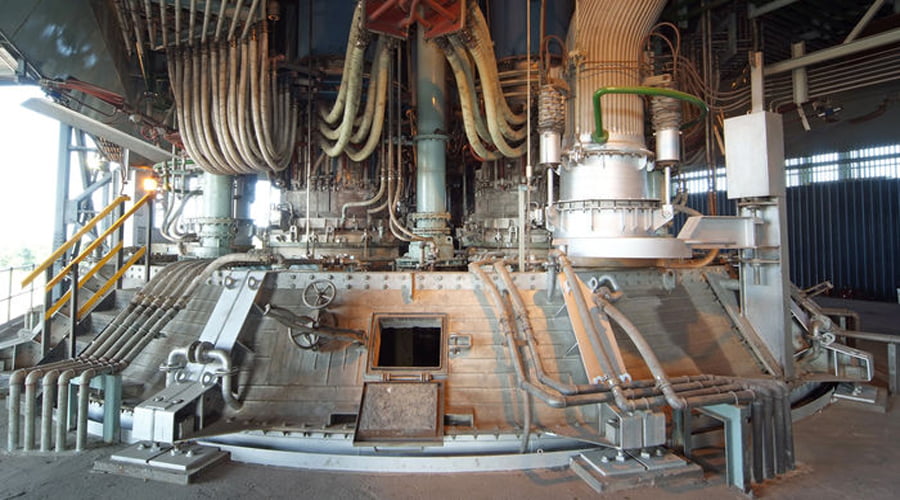

Submerged Arc Furnace Operation Matters

Submerged arc furnace operation play a vital role in various industries such as steelmaking and mineral processing. The article mainly introduces 5 kinds of operation matters.

Submerged Arc Furnace Principle

The article mainly describes the Submerged arc furnace principle, and the range of raw materials that can be smelted, etc.

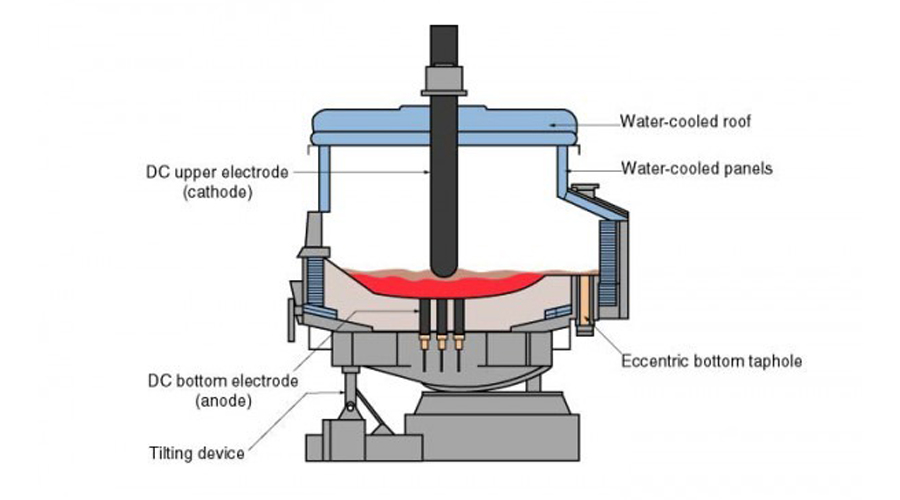

DC Submerged Arc Furnace For Smelting

DC submerged arc furnace is the application of DC to the smelting of the SAF. As a simple structure but high production efficiency in smelting equipment, what are its characteristics?

What is a Submerged Arc Furnace?

What is a submerged arc furnace? What are its main uses and characteristics in the smelting industry.

Submerged Arc Furnace (SAF) Electrode Accident Analysis

Electrode safety accidents are common safety accidents of nonferrous metals and calcium carbide companies in submerged arc furnace(SAF) smelters.

Submerged Arc Furnace Manufacturers In India

Submerged arc furnace manufacturers in India,also known as electric furnaces,are used to reduce smelted ores. It’s hot-selling product in the smelting industry.

Submerged Arc Furnace Process

The main composition structure and characteristics of the submerged arc furnace process are mainly explained.