Electric Furnace Steelmaking Production Develops Rapidly

The electric furnace steel plant is a short-process production process. Compared with the blast furnace-converter combined enterprise, the investment is saved by 2500,

Basic Structure of Submerged Arc Furnace

The submerged arc furnace is a kind of electric furnace body, furnace transformer, high current conductor (short network), electrode system, submerged arc…

Vacuum Induction Melting Furnace Principle

The principle of vacuum induction melting furnace is based on the process of induction heating and vacuum technology. This type of furnace is designed to melt metals in a vacuum environment, which helps to remove impurities and improve the quality of the final product.

Medium Frequency Induction Furnace Structure

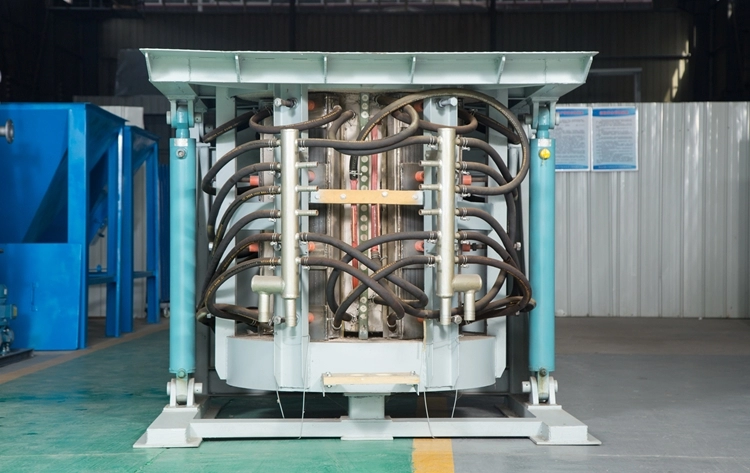

A medium frequency induction furnace is a type of furnace that uses electromagnetic induction to heat materials. It consists of several components that work together to create the necessary conditions for heating and melting metals.

Medium Frequency Coreless Induction Melting Furnace

A medium frequency coreless induction melting furnace is a specialized type of industrial equipment used for the controlled heating and melting of metals.

What is Submerged Arc Furnace for Ferrochrome Production?

Submerged arc furnace (SAF) is a technological marvel inSubmerged arc furnace (SAF) is a technological marvel in the realm of ferrochrome production.

Intelligent Electrode Regulator for Steelmaking EAF

The electrodes used in the EAF play a crucial role in maintaining the arc and controlling the heat input into the furnace. The Intelligent Electrode Regulator

Graphite Electrode for Electric Arc Furnace

Electric Arc Furnace Graphite Electrode is a crucial component in the operation of an EAF. It is responsible for providing the electrical energy required to sustain the electric arc that melts the metal charge in the furnace.

Electric Arc Furnaces Refractory Materials Development

Electric arc furnaces Refractory Materials are widely used in the steel industry for producing high-quality steel at a lower cost compared to traditional method

Electric Arc Furnace Steelmaking Rise and Development

The rise and development of electric arc furnace steelmaking have been a significant milestone in the history of metallurgy. This technology has revolutionized