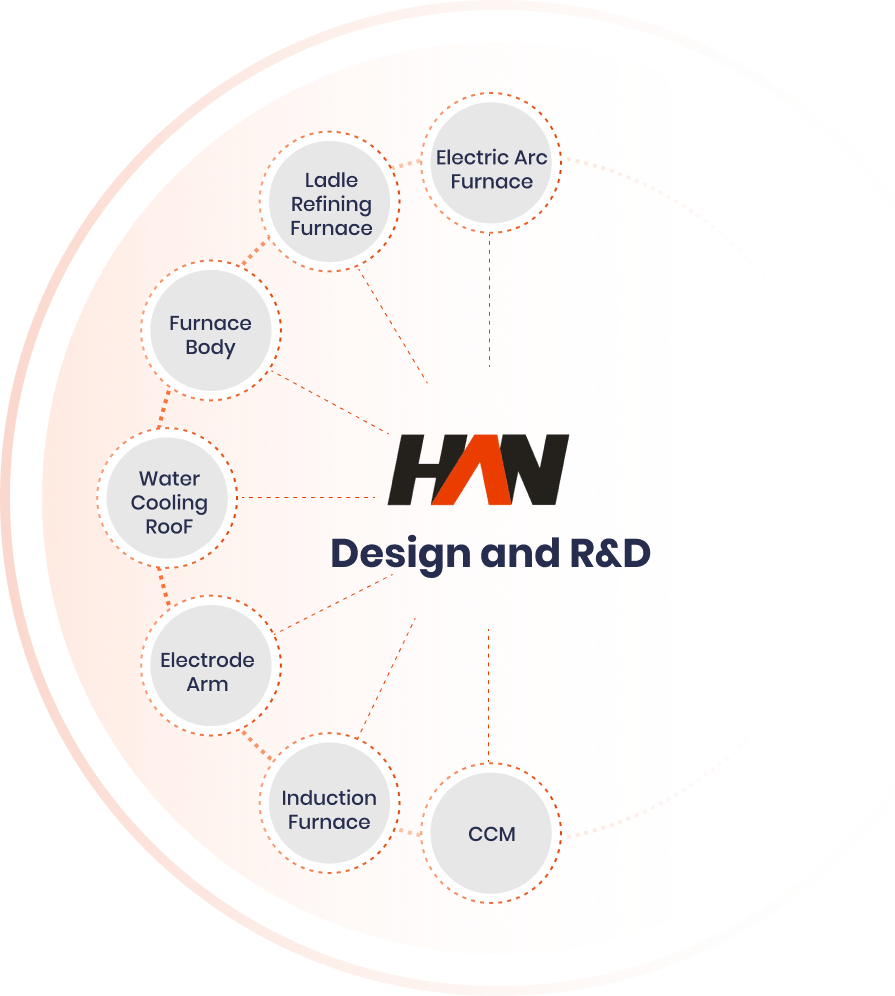

Design and R&D

The electric arc furnace and refining furnace produced by Hani Tech has adopted and innovated the most advanced tubular water-cooled furnace roof technology, tubular water-cooled furnace wall technology, and copper-steel composite plate conductive cross arm technology, EBT tapping technology, and large cross-section at present. Water-cooled cable technology, PLC control technology, high-impedance technology, auxiliary energy technology such as carbon-oxygen lance oxygen burner, oxygen-enriched operation technology, and hot metal hot charging technology have all been applied in electric furnaces.

The design of medium frequency induction furnace equipment includes power supply and electrical control part, furnace body part, transmission device, and water cooling system.

Hani Tech can provide GW series intermediate frequency melting furnace, HQ type precision casting special furnace, GWL series intermediate frequency aluminum melting furnace, GWT series intermediate frequency copper melting furnace, vacuum furnace, and other intermediate frequency melting furnace series; KGCX, IGBT, KGPS series intermediate frequency power supply; fully enclosed cooling tower, pulse bag filter and other intermediate frequency furnace supporting equipment.

The design of continuous caster equipment consists of liquid steel carrier (ladle, rotary table), tundish and its replacement device, mould and its vibration device, secondary water cooling area of continuous caster, pulling straightener, cutting equipment, ingot guiding device, etc.

Automatic control system of continuous caster: full automatic steel pouring control system, slab cooling system of continuous caster, three electric control system of continuous caster (basic automation system, electric drive, and instrument system of continuous caster, power purification device, and anti-interference system)

For a variety of different industrial furnaces and caster equipment, we can achieve more professional and more accurate design and manufacturing. (Our high-quality products have passed the ISO:9001 certificate and we update our manufacturing and management level to international standards.)

HANI Metallurgy has won praises from users and colleagues with its superb technical force, rich manufacturing experience, strict scientific management, and excellent after-sales service.

Electric arc furnace

HX-10t-EAF-layout

HX-12t-EAF-Layout

CCM R6 2 Strand Layout Design

CCM Design

Ladle Furnace 3D

Ladle Furnace 3D

Ladle Furnace 3D