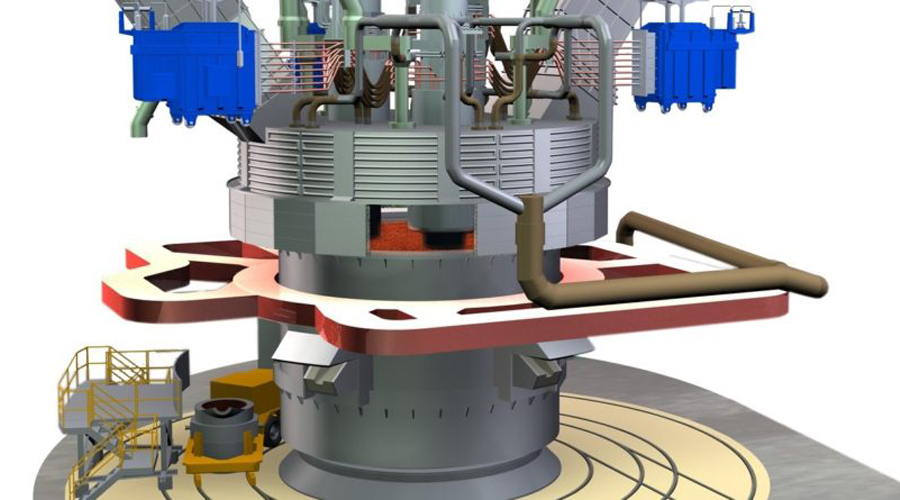

Basic Structure of Submerged Arc Furnace

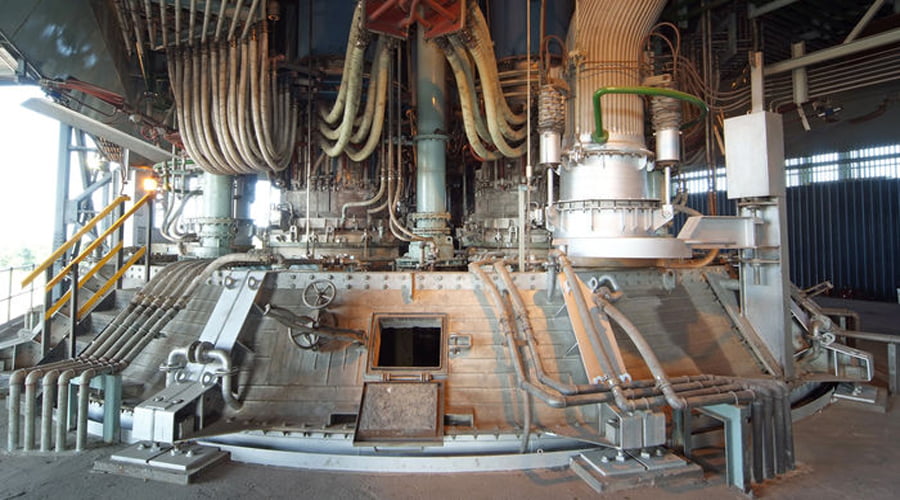

The submerged arc furnace is a kind of electric furnace body, furnace transformer, high current conductor (short network), electrode system, submerged arc…

How Does A Submerged Arc Furnace Work

SAF are important industrial equipment used in the production of various metals. This article explores the inner workings and processes of operating a submersible furnace. Introduces how does a submerged arc furnace work.

What is Submerged Arc Furnace for Ferrochrome Production?

Submerged arc furnace (SAF) is a technological marvel inSubmerged arc furnace (SAF) is a technological marvel in the realm of ferrochrome production.

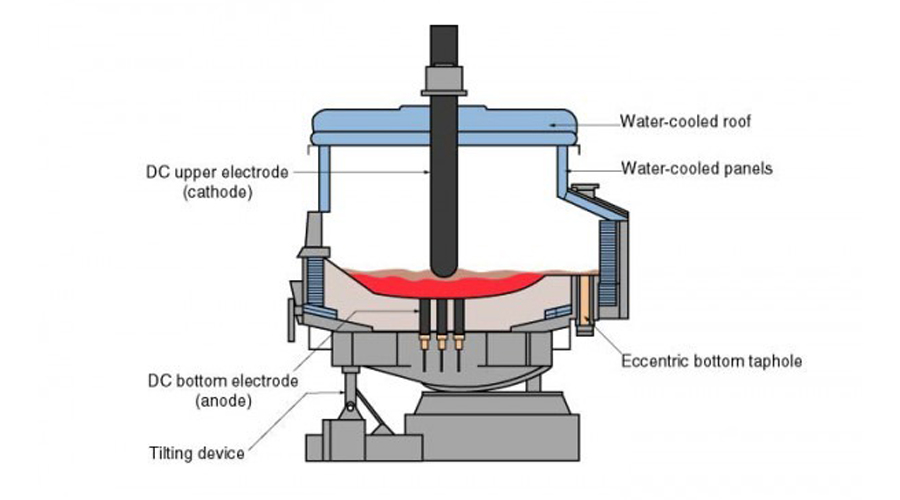

The Role of Submerged Arc Furnace Diagram

Submerged arc furnace diagram is an important step before the production of metal smelting equipment. The purpose of this article is to explore the significance of submerged arc furnace diagrams and their role in the production of various materials through the submerged arc furnace process.

Submerged Arc Furnace For Ferro Alloy Production

This article mainly describes the specific characteristics of submerged arc furnace for ferro alloy production, as well as the principle, advantages and applications of induction furnaces.

Submerged Arc Furnace Operation Matters

Submerged arc furnace operation play a vital role in various industries such as steelmaking and mineral processing. The article mainly introduces 5 kinds of operation matters.

Submerged Arc Furnace Principle

The article mainly describes the Submerged arc furnace principle, and the range of raw materials that can be smelted, etc.

Invitation to the 10th Middle East Egypt International Metal and Steel Exhibition

The 10th Middle East Egypt International Metal and Steel Exhibition will be held from September 2nd to 5th, 2023 in Egypt. We hereby sincerely invite you and your company representatives to visit us at booth B38-2.

Submerged Arc Furnace Electrodes – Self-cultivation Electrode

Submerged arc furnace electrodes the function is to conduct electricity and convert electrical energy into heat energy.What is its process and operation process.

New Trends in Submerged Arc Furnace Technology

This article will give introduce the solution of the online monitoring system for new trends in submerged arc furnace technology in today’s main application fields: ferroalloys, non-ferrous, special application, and recycling.